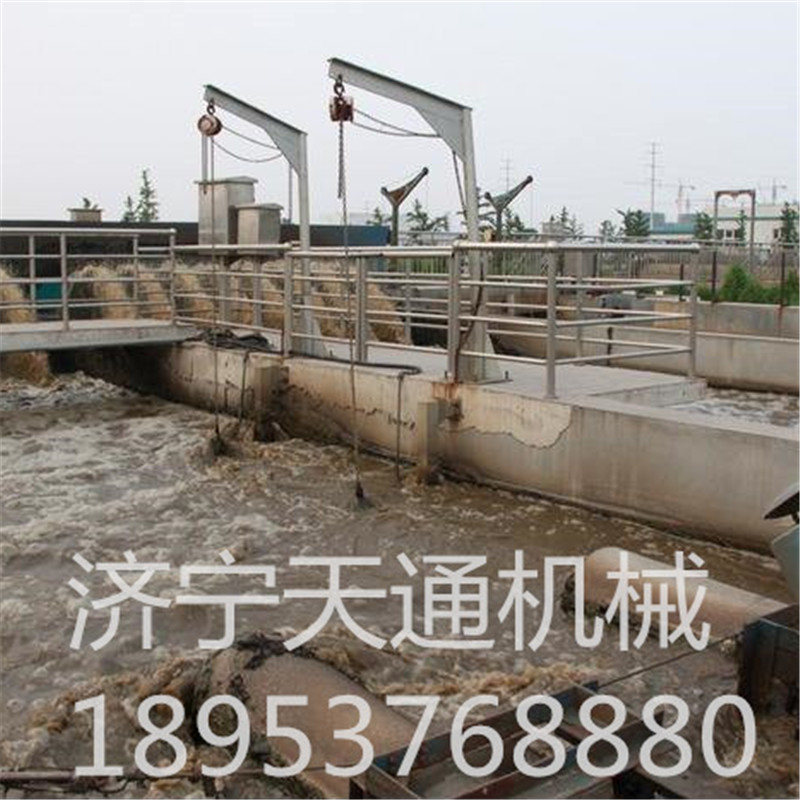

浙江温州某酒精厂废水排放处理污水处理设备案例

- ¥1000.00 ≥ 1台

- 2018-07-24 16:44:35

- 天通

- 其它

- 污水处理设备,酒精厂废水排放处理,造纸厂..

- 浙江温州

- 尹经理 17562010077

- 济宁市天通机械设备有限公司

信息介绍

详细参数

浙江温州某酒精厂废水排放处理污水处理设备案例

浙江温州某酒精厂是采用木薯干原料生产酒精的工厂,年产酒精5万吨、无水乙醇1万吨,每天排放酒精废液1600t。废水处理工程设计规模1600m³/d。

该厂每天排放1600m³(木)薯干酒精废液(每年生产330d),废液COD为55000~60000mg/L,BOD为24000 mg/L,SS为22700mg/L,pH值为4.2。

处理工艺:

薯干酒精废液(原糟液),其COD:BOD=2:1,属于高温、高浓度、高SS、可生化性良好的的有机废液。采用厌氧-好氧法处理(木)薯干酒糟废液能回收大量沼气能源,并能将废液处理达标,是技术和经济均为佳的处理方式。

工艺原理:

由酒精蒸馏塔排出的薯干酒糟废液经废热回收后,进入沉砂池,在沉砂池中尽量将原料夹带的砂石去除。然后进入贮存池水解,再将废液用泵打入Ⅰ级全混合厌氧发酵罐(CSTR)进行高温厌氧发酵,发酵温度52~54℃,pH值控制在7.厌氧发酵罐内装有大型水力喷射泵和厌氧污泥回流装置。喷射泵用于罐内全混合搅拌,并可用于加热、破碎浮渣。厌氧发酵产生的沼气(每立方米COD为55000mg/L的废液可产30m³沼气,热值相当于30KG原煤)经气水分离,水封后进入沼气贮柜,用作锅炉燃料。

由Ⅱ级UASB和气浮装置排出的厌氧污泥送去脱水处理,作有机肥料。由SBR排出的好氧污泥返回酸化池,再进入Ⅰ级厌氧发酵罐处理,还可增加沼气产量。

SBR池:钢制,2座,单池有效容积1060m³,交替进行。

沼气贮柜:湿式贮气柜,容积25000m³,气压350mmH2O。

工程评析

工程借鉴了轻工业环境保护研究所20多年来治理酒精(木薯干原料)废液的经验和工程实践,采用二级厌氧发酵,互为补充。将Ⅰ级和Ⅱ级串联,可获得厌氧微生物处理的佳效果,克服了仅采用厌氧处理难以达标的缺点。

Treatment process:

Potato alcohol wastewater (original stillage), the COD:BOD=2:1, which belongs to the high temperature, high concentration, high SS, biochemical organic waste of good. Using anaerobic aerobic treatment (wood) potato vinasse of biogas energy recycling, and waste treatment standards, technical and economic are the best way to.

Process principle:

Potato production wastewater discharged from the alcohol distillation tower by waste heat recovery after entering the sand pool in the grit chamber as raw material entrained sand removal. Then the hydrolysis was carried into the storage tank, then the waste liquid was pumped into the first level full mixed anaerobic fermentation tank (CSTR) by the pump to conduct high-temperature anaerobic fermentation. The fermentation temperature was 52~54 pH, and the pH value was controlled in 7. anaerobic fermentation tank, equipped with large hydraulic jet pump and anaerobic sludge reflux device. The jet pump is used in the mixing and mixing in the tank and can be used to heat and break the dross. Anaerobic fermentation to produce biogas (COD per cubic meter of 55000mg/L wastewater can produce 30m fand corresponding to 30KG coal gas, the calorific value of the gas and water separation, water) into the biogas storage cabinet, used as boiler fuel.

The anaerobic sludge discharged from the second class UASB and the air floatation device is dehydrated to be a high quality organic fertilizer. The aerobic sludge discharged by SBR is returned to the acidification tank and then into the stage I anaerobic fermentation tank, and the biogas production can also be increased.

SBR pool: steel, 2 seat, single cell 1060m volume fand alternately.

Biogas storage cabinet: wet gas holder, pressure volume 25000m fand, 350mmH2O.

- 天通

- 污水处理设备,酒精厂废水排放处理,造纸厂..

- 污水处理成套设备

- 浙江温州

- 尹经理

- 天通

- 其它

- 是

污水处理设备信息

-

电气焊烟雾净化器节能烟雾净化器电焊烟雾烟尘净化器¥ 2350

电气焊烟雾净化器节能烟雾净化器电焊烟雾烟尘净化器¥ 2350 -

深圳宝安激光焊接机排名,东莞水槽全自动激光焊接机¥ 30

深圳宝安激光焊接机排名,东莞水槽全自动激光焊接机¥ 30 -

杭州专业的三维动画机械系统原理动画生产工艺流程动画公司¥ 5000

杭州专业的三维动画机械系统原理动画生产工艺流程动画公司¥ 5000 -

湖北武汉虎牌保温杯总代理商专卖店¥ 1

湖北武汉虎牌保温杯总代理商专卖店¥ 1 -

万宁景区栅栏批发三沙酒店围栏供应三亚锌钢护栏现货¥ 100

万宁景区栅栏批发三沙酒店围栏供应三亚锌钢护栏现货¥ 100 -

瑞安日报广告部发布声明公告电话面议

瑞安日报广告部发布声明公告电话面议