高温无机粘合剂875

- 面议

- 2024-12-28 11:41:41

- 分立式

- 高温无机粘合剂,粘合剂880,644-A,高温无..

- 福建厦门

- 石金良 15396145919

- 厦门良厦贸易有限公司

信息介绍

详细参数

42

An acidic, etching solution which is ideal for use

in adhesive systems for bonding non-porous

ceramics and glass. Stable when mixed with copper.

Reacts with bases such as carbonates, oxides and

hydroxides of alkali metals.

642

A basic solution which is highly compatible with

most ceramic and metal powders. Good wettability

and tack, and excellent acid resistance after

curing. Extremely moisture resistant after a high

temperature cure. Sets up in thick cross-sections

when properly formulated.

643-1

A basic solution compatible with most ceramic and

metal powders. Excellent binder for producing high

temperature protective coatings and refractory and

chemically resistant adhesives and patching materials.

Fully cures at low temperatures and sets up in thick

cross-sections when properly formulated.

643-2

Similar to 643-1. Excellent for formulating thin coatings

that set at room temperature and can be raised rapidly

to high temperatures.

644-A

An acidic, colloidal alumina binder developed for

mixing with sized refractory flours and grains to

produce high temperature refractory coatings for

ceramic fiber boards. Used as a superior standalone

system to rigidize refractory fiber shapes.

HIGH TEMPERATURE INORGANIC BINDERS

Technical Bulletin A11

Ceramabind™ 542 seals porosity in ceramic plate.

Product

542

642

642A

643-1

643-2

644-A

644-S

830

875

880

pH

2.5

10.7

10.7

11.0

11.5

4.0

9.0

11.4

2.8

6.5

Specific Gravity,

g/cc

1.47

1.41

1.25

1.26

1.27

1.23

1.40

1.20

1.36

1.04

Viscosity,

cP

50

370

200

60

30

7

35

10

NA

480

Solids Content,

% by weight

40

40

25

30

30

30

40

25

100

50

Temperature Resistance,

ºF (ºC)

3200 (1760)

3000 (1650)

3000 (1650)

3000 (1650)

3000 (1650)

3000 (1650)

3200 (1760)

2000 (1093)

3000 (1650)

1200 (650)

TYPICAL PRODUCT SPECIFICATIONS

644-S

A colloidal silica aqueous solution which produces high

adhesive strength. Ideal for blending with all types of

granular and fibrous ceramics. Excellent resistance to

temperature, moisture and mechanical shock.

830

A basic solution compatible with most oxide and metal

powders. Ideal for formulating high pigment-to-binder

ratios to produce dense adhesives and coatings. Sets

at room temperature to a moisture resistant film and

does not require a heat cure. Use only for thin coating

systems less than 1 mil thick.

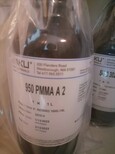

875

An acidic powdered binder system used to formulate

high strength, hydraulic-setting cements for electrical

potting or molding applications. A powder blend is

typically formulated by adding one part binder to four

parts filler by weight. Water is then added in a ratio of

15–20 parts to 100 parts powder blend by weight.

880

High temperature, water-dispersible silicone resin for

producing corrosion and moisture resistant coatings

and sealing porous ceramics.

Aremco’s Ceramabind™ materials are unique

inorganic, water-based binder systems used in the

formulation of specialty adhesives, coatings, sealants

and putties for applications to 3200 ºF. The versatility

of Aremco’s Ceramabind™ products enables users

to blend formulations using most ceramic, glass and

metal-oxide powders. Specific properties such as

coefficient of thermal expansion, thermal conductivity,

dielectric strength, and chemical and moisture

resistance can be optimized.

- 高温无机粘合剂,粘合剂880,644-A,高温无..

- 特殊仪器仪表配件

- 福建厦门

- 石金良

- 分立式

- 指针式