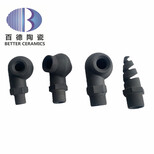

百德厂家碳化硅喷嘴喷头型号现货充足支持定制

- ¥80.00 ≥ 1000个

- 2020-09-03 08:11:05

- 百德

- 潍坊

- 碳化硅喷嘴,碳化硅喷头,SISIC喷嘴,吸收塔..

- 山东潍坊

- 李荆 13563624080

- 潍坊百德机械设备有限公司

信息介绍

详细参数

在湿法烟气脱硫工艺中,常用于喷淋塔的喷嘴有5种,现简介如下:

①空心锥旋流喷嘴(hollowconeswirl nozzle)

这种喷嘴,石灰石浆液从切向进入喷嘴的涡旋腔内,然后从与入口方向成直角的喷孔喷出,可允许自由通过的颗粒尺寸大约是喷孔尺寸的80%-100%,喷嘴无内部分离部件

传统的用于湿法烟气脱硫系统的喷嘴是采用炭化硅材料铸造的空心锥旋流喷嘴,通常在O.1-0.2MPa压力下工作,旋流切线型喷嘴与相似的传统实心锥旋流喷嘴相比,前者比后者的自由畅通直径要大许多,尤其是在喷射循环使用的石灰石浆液时更实用。

②实心锥旋流喷嘴(fullconeswirlnozzle)

这种喷嘴的设计思路与空心锥旋流喷嘴相似,所不同的是涡旋腔封闭端的顶部使部分液体转向喷入喷雾区中央,以此来实现实心锥形喷雾效果。该喷嘴允许通过颗粒的尺寸为喷孔直径的80%-100%,喷射的液滴平均粒径比相同尺寸的空心锥形喷嘴的大30%.50%,在吸收塔中应用时可以采用氮连接碳化硅陶瓷材料(SNBSC)。

③双空心锥旋流喷嘴(doublehollowconeswirl nozzle)

该喷嘴是在一个空心锥切线腔体上设计两个喷孔.在吸收塔中,一个喷孔向下喷,另一个喷孔向上喷:这种喷嘴允许通过的颗粒尺寸为喷孔直径的80%一100%

④实心锥喷嘴(fullcorlenozzle)

这种喷嘴通过内部叶片使石灰浆液形成旋流,然后与入口的轴线同轴从喷孔喷山,根据不同设计,喷嘴允许通过的人颗粒直径为喷孔直径的25%-100%不等,同等条下,这种喷嘴提供的雾化粒径相当丁相同尺寸的空心锥切线刊喷嘴的60%-70%。其缺点就是能耗较高。

⑤螺旋型喷嘴(spiralnozzle)

此喷嘴是由连续变小的螺旋线体组成,石灰石浆液不断经螺旋线相切后改变方向成片状喷射成同心轴状锥体。这种喷嘴无分离部件,自由畅通直径等于喷孔直径的30%-100%,同等条件下该喷嘴的平均粒径相当于同尺寸的空心锥旋流喷嘴的50%-60%。而且此喷嘴的操作压力一般在0.05MPa-O.1MPa。

undefined

脱硫喷嘴 Desulphurization Spray Nozzle

脱硫喷嘴是电厂吸收塔、大型锅炉,钢厂烧结机脱硫等脱硫除尘成套装置的关键部件。材质包括反应烧结碳化硅、不锈钢316L等。碳化硅材质脱硫喷嘴具有高强度、高硬度、抗腐蚀剧烈磨损、耐高温等优良的性能,在恶劣的条件下,使用寿命长。我公司生产的脱硫喷嘴费雾液滴分布均匀、流道通畅,无阻塞现象。目前有螺旋实心锥型、涡流空心锥型、涡流实心锥型,液柱型等多个品种。

Desulfurization of spray nozzle is the key components of a large power plant absorption tower,boiler, steel sintering desulfurization desulfurization dusting of complete sets of equipment. The Material has reaction sintered silicon carbide and stainless steel 316 I, etc. SISIC desulfurizationnozzle has the advantages of high strength, high hardness, strong corrosion resistance, high wearresistance, high temperature resistance and other excellent properties. The desulfurization nozzle, ofour company has good spray droplet distribution is uniform, smooth flow channel, no blockingphenomenon. At present, there are many kinds of spiral solid cone type, vortex hollow cone typevortex solid cone type, liquid column type and so on.

undefined

喷嘴的技术要求Technical requirements for nozzles

喷嘴布置的间距应合理,要使喷嘴喷出的锥形水雾相互搭接,不留空隙,否则烟气可能接触不到也低就从空隙中溜走,调整喷嘴布置密度和喷淋层数,可获得不同的喷雾重叠度。重叠度越高,脱硫效率也就越高,但阻力也会增加。一般喷雾重叠度为200%-300%,同时喷嘴布置的另一要求是不冲刷塔壁,喷淋母管和支撑件(未避免塔壁防腐材料,可将吸收塔外圈喷嘴布置90°或者涡流实心锥喷嘴)。

The spacing of the nozzles should be reasonable. The conical water mist sprayed from the nozzles should be overlapped with each other, leaving no gaps. Otherwise, the flue gas may not touch the droplets and slip away from the gaps. Adjust the nozzle placement density and the number of spray layers. Different spray overlaps are available. The higher the degree of overlap, the higher the desulfurization efficiency, but the resistance will also increase.Generally, the spray overlap is 200%-300%, and another requirement of the nozzle arrangement is not to wash the tower wall, spray the mother tube and the support member(the tower wall anti-corrosion material is not avoided, the nozzle of the outer ring of the absorption tower can be arranged 90°or Vortex solid cone nozzle).

喷嘴的角度Angle of the nozzle

喷雾角是指浆液离开喷嘴口后形成的液膜锥的锥角,主要受喷嘴孔半径、旋转室半径和浆液入口半径等因素影响。选择喷雾角时,与喷嘴在塔内布置相结合,塔内覆盖均匀度与覆盖率,通常要求喷淋角为90°-120°。

The spray angle refers to the cone angle of the liquid film cone formed after the slurry leaves the nozzle port, and is mainly affected by factors such as the nozzle hole radius, the radius of the rotating chamber, and the radius of the slurry inlet. When selecting the spray angle, it must be combined with the nozzle arrangement in the tower to ensure uniform coverage and coverage within the tower, usually requiring a spray angle of 90°to 120°.

undefined

喷嘴的压力Nozzle pressure

喷嘴的喷嘴压降是指浆液通过喷嘴通道时所产生的压力损失,主要与喷嘴结构参数和浆液粘度等因素有关。压降大,系统能耗也大。一般喷淋系统喷嘴压降典型值为0.05-0.15MPa之间。

The nozzle pressure drop of the nozzle refers to the pressure loss generated when the slurry passes through the nozzle passage, which is mainly related to factors such as nozzle structure parameters and slurry viscosity. The greater the pressure drop, the greater the system's energy consumption. Typical nozzle system pressure drop is typically between 0.05and0.15Mpa.

喷嘴的流量Nozzle flow

喷嘴流量指单位时间内通过的体积流量,喷嘴流量与喷嘴压力降、喷嘴结构参数等因素有关。在相同喷嘴压力降条件下,喷嘴孔半径大,喷嘴流量大。

The nozzle flow rate refers to the volume flow rate through the nozzle per unit time, and the nozzle flow rate is related to the nozzle pressure drop and the nozzle structure parameters.Under the same nozzle pressure drop condition, the larger the nozzle hole radius, the larger the nozzle flow rate.

喷嘴的流量终将影响脱硫系统的经济性,在给定的吸收塔中,选用流量大的喷嘴可以减少所需喷嘴的总数,从而降低系统的造价,大流量喷嘴的限制少且防堵塞性能好,这样可有效地节约运行和维护费用。但选用大流量嘴也有所牺牲,其液滴尺寸要増大,所以不同喷嘴可接受的流量度受到这种喷嘴雾化效果的限制。

产品简介

The flow rate of the nozzle will ultimately affect the economics of the desulfurization system.In a given absorption tower, the nozzle with a large flow rate can reduce the total number of nozzles required, thereby reducing the cost of the system. The limitation of the large flow nozzle is small and the anti-clogging performance is good. This can effectively save operating and maintenance costs. However, the use of large flow nozzles has also been sacrificed, and the droplet size is increased, so the maximum flow rate acceptable for different nozzles is limited by the atomization effect of such nozzles.

平均粒径及雾滴粒径分布 Average particle size and droplet size distribution

喷嘴的雾化性能取决于浆液进口压力、浆液的黏度、表面张力和喷嘴结构参数等。当喷嘴进口压力越大,喷嘴压力降越大,通过喷嘴的流量越大,而喷嘴雾化浆滴平均直径越小。

The atomization performance of the nozzle depends on the slurry inlet pressure, slurry viscosity, surface tension and nozzle structure parameters. The greater the nozzle inlet pressure, the greater the nozzle pressure drop, the greater the flow through the nozzle, and the smaller the average diameter of the nozzle atomized slurry.

undefined

喷嘴的喷雾雾滴粒径分布对于多数应用都很重要,对于湿法脱硫系统更是有非常重要的意义。对于某一特定的工况而言,脱硫塔内的雾滴粒径有一个优值。如果喷出与优值粒径均匀度很高的雾滴,就能减少投资及实现系统的经済运行。

The spray droplet size distribution of the nozzle is important for most applications and is of great importance for wet desulfurization systems. For a particular operating condition, the particle size of the droplets in the desulfurization tower has an optimum value.If a droplet with a uniform particle size uniformity can be ejected,the investment and economic operation of the system can be reduced.

自由畅通直径 Free and unobstructed diameter

367b4a76261ef8df5f8358f237f466

自由畅通直径是指喷嘴允许通过球形杂质的直径。自由畅通直径大,其防堵塞的性能越好。

The free unobstructed diameter refers to the maximum diameter of

the nozzle that allows passage of spherical impurities.The larger the free diameter,the better the anti-clogging performance.

undefined

百德公司承诺产品生产周期在客户要求时间内,产品包装要求泡沫垫隔多层包装,中途无损耗,破损由供方承担,发货方式物流快递定日达。百德喷嘴可提供合格证书及产品检验报告,质保一年以上。

1、交货期:如有库存,将在三天内发货,如无库存,生产周期为15天。

2、包装方式及运输:产品采用泡沫垫隔包装,中途无损耗,产品中途破损供方承担。

3、含税报价,为13%增值税。

4、付款方式为:电议。

5、所有碳化硅制品出厂前全部检验,质保一年。

6、如果对上述条款有任何问题,请随时向我们垂询。

Baide company promises that the production cycle of the product will be within the time required by customers, and the product packaging will require foam gasket to be packed at multiple levels, with no wear and tear, damage borne by the supplier, and delivery mode logistics express delivery will reach the date of delivery. Baide nozzle can provide certificate of competency and product inspection report, warranty for more than one year.

1、Delivery date: if there is stock, it will be shipped within three days, if there is no inventory, the production cycle will be 15 days.

2、Packaging and transportation: the product is packed with foam pad, without wear and tear, and the supplier is responsible for the breakage of the product.

3、The tax-inclusive quotation is 13% value-added tax.

4、The payment method is as follows:

5、All the silicon carbide products shall be inspected for one year before leaving the factory.

6、 If there is any problem with the above clauses, please contact us at any time.

undefined

山东百德陶瓷科技有限公司(滩坊百德机械设备有限公司)是一家生产反应烧结碳化硅陶瓷的企业,公司位于诺贝尔文学奖获得者英言的家乡高密市,地处胶东半岛和山东内陆的结合部,东临旅游名城青岛,西依世界风筝之都潍坊,境内交通便利,铁路公路四通八达,距离青岛机场仅40分钟车程,热烈欢迎新老客户到厂考察。

公司生产的碳化硅制品性能稳定,品质优良,已通过ISO9001质量体系认证。产品具有高强度,高硬度,耐高温,耐磨损,耐腐蚀,耐急冷急热,抗热震性能好,导热好,热等特点。产品广泛适用于电厂脱硫除尘设备,陶瓷高温窑炉,钢厂淬火炉,矿山物料分级旋流器等等,产品分类涵盖碳化硅脱硫喷嘴、碳化硅喷火嘴套管、碳化硅换热器、辐射管内管、辐射管外管、碳化硅辊棒、碳化硅方梁、碳化硅坩埚等。

公司拥有的研发设计模具开发团队,可按客户要求定制各式产品。

百德一直奉行“进取 诚信 严谨 团结”的方针,不断开拓创新,以技术为核心、视质量为生命、奉用户为上帝,竭诚为您提供的碳化硅产品以及无微不至的售后服务。

我们始终相信,的产品和诚信的服务是维护客户与我长期合作的。

cb3ced2ce7900f217b9275e95011bf

Weifang Better Ceramics co., LTD is a professional production of Reaction Sintered Silicon Carbide (RBSiC) Or Silincon Infiltrated Silicon Carbide (SiSiC) ceramics enterprises,Our company is located in gaomi city located in the jiaodong peninsula and shandong inland junction,in the west of tourist city of Qingdao, the esst to the world kite city of weifang, the territory of convenient transportation, convenient railway highway from Qingdao airport only 40 minutes, we warmly welcome new and old customers to plant inspection.

BETTER’S RBSiC(SiSiC) products have stable performance and excellent quality, Our company has passed ISO9001 quality system certification. RBSiC(SiSiC) Product has high strength, high hardness, high temperature resistance, wear resistance, corrosion resistance, oxidation resistance, thermal shock resistance, good thermal shock resistance, good thermal conductivity, high thermal efficiency, etc. Our Products are widely applied in power plant desulfurization dust removal equipment, high temperature ceramic kiln, steel quenching furnace, mine material grading cyclone, etc., RBSiC(SiSiC) product categories include Desulfurization spray nozzle, RBSiC(SiSiC) burner nozzles, RBSiC(SiSiC) radiation pipe, RBSiC(SiSiC) heat exchanger, RBSiC(SiSiC) beams, RBSiC(SiSiC) rollers, RBSic(SiSiC) lining ect.

BETTER has a professional research and development design mold development team, can be customized according to customer's request all kinds of products. "It has been under enterprise integrity rigorous unity" principle, constantly blaze new trails, technology as the core, regard quality as life, serve customers as god, sincerely to provide you with the highest ratio of silicon carbide products, high quality product design modification and meticulous after-sales service.

We always believe that high quality products and sincere service is the only guarantee maintain customers long-term cooperation with me.

如有问题,欢迎垂询

undefined

undefined

- 百德

- 碳化硅喷嘴,碳化硅喷头,SISIC喷嘴,吸收塔..

- 喷嘴/喷头

- 山东潍坊

- 李荆

- 百德

- 潍坊

- 可定制

- 是

- 5

- 法兰

- 雾化

- 脱硫塔

- 空心锥

- 外螺纹连接

- 喷雾

喷嘴信息

-

实体厂家批发高压胶管高压蒸汽胶管大口径高压胶管液压油管¥ 30

实体厂家批发高压胶管高压蒸汽胶管大口径高压胶管液压油管¥ 30 -

佛山不锈钢玻璃护栏连接立柱车站玻璃立柱医院护栏扶手连接件面议

佛山不锈钢玻璃护栏连接立柱车站玻璃立柱医院护栏扶手连接件面议 -

蓝金蓝莓苗蓝金蓝莓苗种植时间¥ 10

蓝金蓝莓苗蓝金蓝莓苗种植时间¥ 10 -

方山安利产品店铺咨询电话方山安利产品沐浴露经销商¥ 95

方山安利产品店铺咨询电话方山安利产品沐浴露经销商¥ 95 -

佛山均安金刚砂起灰处理、乐从金刚砂硬化地坪面议

佛山均安金刚砂起灰处理、乐从金刚砂硬化地坪面议 -

废铜回收指导报价——正规回收企业¥ 58000

废铜回收指导报价——正规回收企业¥ 58000