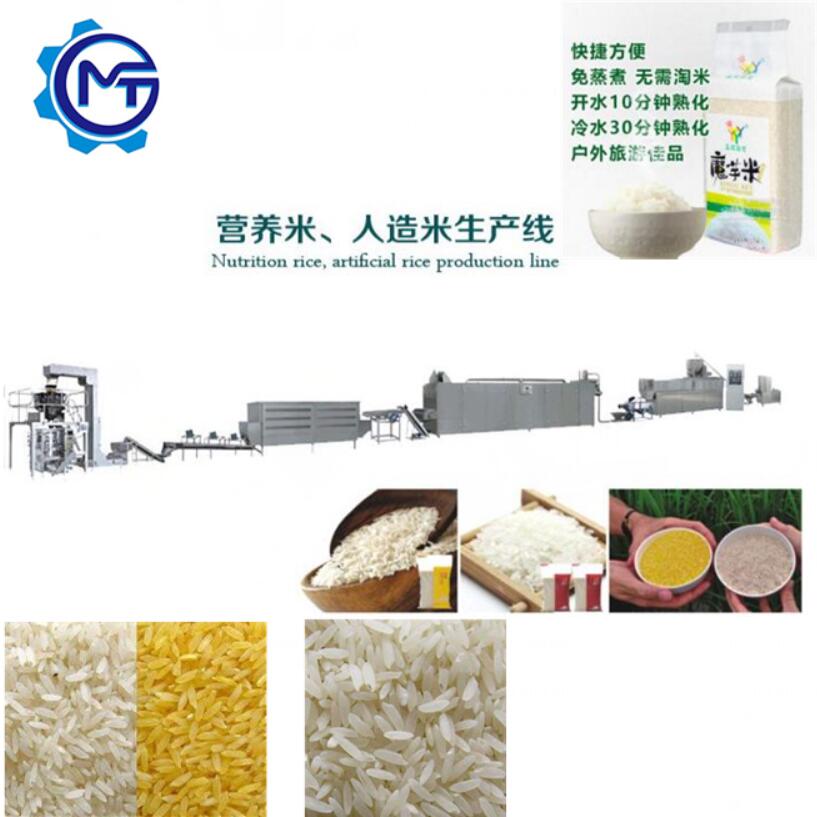

DIY环保降解仿真大米设备人造米粒机器

- ¥48000.00 ≥ 1台

- 2025-02-08 04:12:30

- 山东

- 美腾

- 仿真大米设备,人造米设备,富硒大米设备,..

- 程经理 15562606028

- 济南美腾机械设备有限公司

信息介绍

详细参数

DIY环保降解仿真大米设备 人造米粒机器 农业大学LMH70人造米设备 仿真大米生产线厂家设备 湖济南营养米设备UTE型营养米生产线供应商 PJG冲泡型人造米生产线 代餐粉设备加工厂家 ETE福建重组米人造米设备 营养米生产线操作简单 人造米机器 即食米饭生产线 自加热米饭设备

The dryer adopts low temperature, strengthened circulation air, strong moisture removal for drying, which can ensure the natural color of materials, full shape, not easy to deform, nutrition components do not lose, the equipment has a high degree of automation, there is no need for a person to watch, drying process is completely controlled by microcomputer.

1, hot air in the dryer closed cycle, high thermal efficiency, energy saving.And equipped with a hot air recovery device, fully save energy, the equipment has no secondary pollution, in line with the national food hygiene standards.

2. The box is equipped with a high-strength circular axial flow fan, which promotes the forced circulation of hot air inside the box, and makes the temperature difference between the top and bottom of the dryer small, so that the material stored in a hot air circulation state has enough air volume and heat, so that the drying of flowers is more uniform and the time is faster.

3. Unique air duct allows hot air to blow to flowers according to better heat demand, ensuring uniform drying of materials and avoiding uneven drying inside and outside. This equipment does not need to pour plate in the drying process, which can save energy and manpower.

4. Automatic control of the temperature in the dryer. When the temperature exceeds the set maximum temperature, the power will be automatically cut off, and when the temperature is lower than the set temperature, the power will be automatically supplied;Automatic control of humidity. When the humidity in the box reaches the level needed to be dehumidified, the system will automatically open the dehumidification outlet, discharge the excess moisture in the box in time, and ensure the proper temperature and humidity required for drying (including automatic heating, automatic dehumidification system and automatic circulating air system).

5. Automatic control of drying time, truly realizing automatic management.

6, using 40-70 degrees of relatively low temperature drying, drying, high quality, not broken, good color, good nutritional elements.

粮食是人类获取营养的主要来源之一,但是一般谷物的营养元素含量各不相同.由于谷物在加工过程中损失大量蛋白质和微量元素,使营养成分大大降低,人造大米 (仿真食品)技术是挤压原理在粮食再生利用方面的突破.该技术特点是将人体所必需的各种营养素添加到食品中,生产出各种保健食品,疗效食品和功能食品.产品食用方便,易于消化吸收,深受消费者欢迎.

产品说明

从左至右:原料混合→ 挤压成型→ 一次干燥→ 二次干燥→ 抛光→ 筛选→ 包装

人造米是指淀粉类原料添加各种营养强化物质,用人工方法造粒、糊化、干燥制成与天然大米相似之颗粒。人造米以1:200~300的比例与大米混合,使混合后的米煮成的米饭的营养价值显著优于普通米饭。

中文名

原料配方

主要原料为薯类或玉米淀粉、碎米和面粉。此外尚需添加少量固结剂,如氯化钙、碱类及干酵素等。淀粉质量要较好,面粉量好使用面筋含量较高的强力粉或中薄力粉,以增加粘结力。碎米可增加风味,降低米粒的透明度。

淀粉用量可为30~70%,但适宜用量为40~50%,面粉用量应占原料总用量的30%以上。佳配合率是薯类淀粉40%,薄力粉40%,碎米粉20%;或者薯类淀粉50%,强力粉30%,碎米粉20%。

- 美腾

- 仿真大米设备,人造米设备,富硒大米设备,..

- 膨化机械

- 程经理

- 山东

- 美腾

- 45KW

- 是

- 休闲食品厂设备

- 新品