新型配电箱生产设备基业箱全自动生产线动力箱全自动生产线照明箱全自动生产线厂家

- ¥96325.00 ≥ 1套

- 2019-09-24 08:12:08

- 新型配电箱生产设备,基业箱全自动生产线,..

- 邓贵清 18053635570

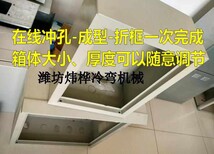

- 潍坊炜桦冷弯机械制造有限公司

信息介绍

详细参数

新型配电箱生产设备 基业箱全自动生产线 动力箱全自动生产线 照明箱全自动生产线厂家

基业箱全自动成型设备

Fully Automatic Forming Equipment for Base Box

我公司生产的电气柜成型设备有以下几个优点:

The electric cabinet forming equipment produced by our company has the following advantages:

“炜桦冷弯”提供的电气柜成型生产线为定制化设备,可根据客户的不同需求,集成生产所需的众多工艺,如自动换料机、切割和冲压系统,以及复杂的焊接、铆接、折弯、搬运和包装等系统。这些都将为生产能力和产品品质带来提高。全自动化冷弯成型生产线设备轧制材料的材质包括:冷轧钢带、热轧钢带、酸洗板(钢带)、彩钢板(钢带)、镀锌钢带和不锈钢带等;设备能处理0.2mm—12mm厚金属板材;生产出来的型材尺寸精度可以控制在0.05毫米以内,这在国内具有行业地位。

The electric cabinet forming production line provided by "Weibi Cold Bending" is customized equipment. It can integrate many processes required for production according to different needs of customers, such as automatic feeder, cutting and stamping system, and complex welding, riveting, bending, handling and packaging systems. All of these will greatly improve the production capacity and product quality. The materials of rolling materials for automatic cold bending production line equipment include: cold rolled steel strip, hot rolled steel strip, pickling plate (steel strip), color steel strip (steel strip), galvanized steel strip and stainless steel strip; high precision equipment can handle 0.2mm-12mm thick metal sheet; the dimension accuracy of the profiles produced can be controlled within 0.05mm, which has a leading position in the domestic industry.

材料规格:Q235

Material Specification: Q235

生产速度:0-8 m/min

Production speed: 0-8 m/min

切断方式:液压切断

Cut-off mode: hydraulic cut-off

电压参数:380V/415V,50Hz, 3相

Voltage parameters: 380V/415V, 50Hz, 3-phase

电气控制:PLC

Electrical control: PLC

- 新型配电箱生产设备,基业箱全自动生产线,..

- 金属成型设备

- 邓贵清

新型配电箱生产设备信息

-

海北代做资金申请报告做好的计划书¥ 8

海北代做资金申请报告做好的计划书¥ 8 -

怎么加盟幸福加贝花甲粉面议

怎么加盟幸福加贝花甲粉面议 -

土石方破碎劈裂机新疆库尔勒¥ 7980

土石方破碎劈裂机新疆库尔勒¥ 7980 -

太仓成人学会计去哪报名太仓会计实操好学吗¥ 1

太仓成人学会计去哪报名太仓会计实操好学吗¥ 1 -

甘肃兰州pvc花坛栅栏pvc花坛栏杆¥ 8

甘肃兰州pvc花坛栅栏pvc花坛栏杆¥ 8 -

滨州哪里的木方便宜¥ 998

滨州哪里的木方便宜¥ 998