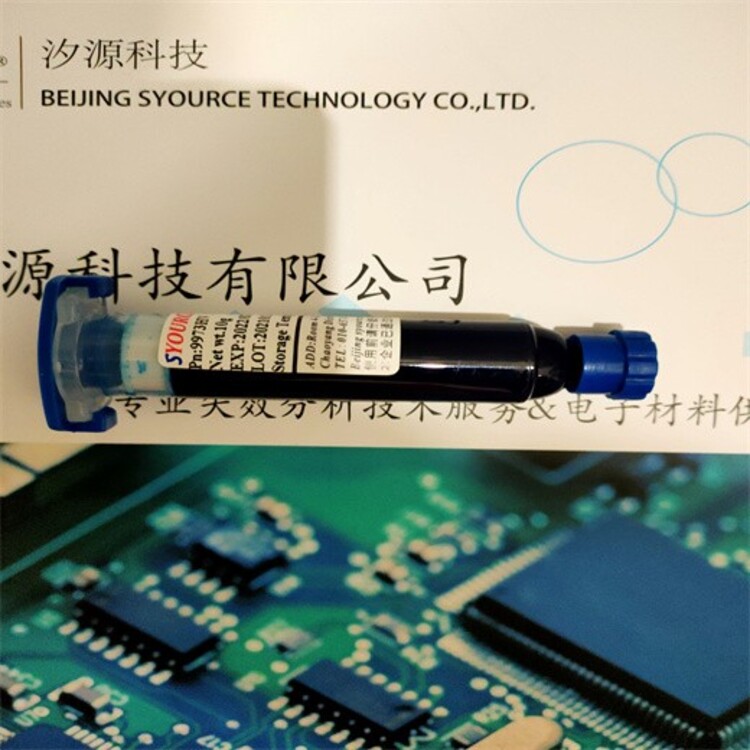

湾泰芯片键合固定蜡,黑龙江湾泰晶圆临时固定石蜡

- 面议

- 2024-12-12 01:03:07

- 晶圆临时固定石蜡,芯片键合固定蜡,芯片键..

- 徐发杰 18515625676

- 北京汐源科技有限公司

信息介绍

详细参数

VALTRON® TriAct™ DF dicing fluid series are formulated with nonionic surfactants, disinfecting actives and other functional

ingredients for application in the semiconductor wafer dicing process. They eliminate silicon dust particles effectively, disinfect

production system pipelines, provide easy rinse with low and fast collapsing foam profile, help to stop microbial growth activity in

concentrate or low dilution, prevents corrosion, and reduces and neutralizes static charges. In addition to cleaning, VALTRON®

TriAct™ DF series lubricate the dicing blades, which lowers friction and surface tension dramatically at dilution rate up to 1:4000, and

acts as a coolant, which reduces heat that causes cracks in the silicon wafer.

应用程序

VALTRON®TriAct™DF切丁液在大多数情况下都是有效的

调剂系统。所述切丁液以液体形式供应

浓缩稀释用去离子水1:2000至

1:40 000,但根据种类和数量而有所不同

污染被移除。

消毒:

使用(消除现有微生物生长):

1:20 ~ 1:40稀释。

日常使用:1:2000至1:2000

特的功能

•在高加工速度下具有高粘结强度

•高软化点和熔点

•粘度低,流动性好

•超紧TTVVALTRON®UltraLux™的涂层可以通过旋转涂层机完成

或理想的涂层方法。溶剂可以被蒸发掉

烘烤(推荐温度为100°C-120°C)。挂载

基材到所需的基材载体板上。拆卸可以

通过浸渍和浸泡粘附的衬底来完成

放入异丙醇浴中。为了加速

拆装过程中,在40°C-60°C加热IPA浴

推荐。使用IPA可以清洁基板

或使用VALTRON®SP2200洗涤剂进行精密清洗。

- 晶圆临时固定石蜡,芯片键合固定蜡,芯片键..

- AB胶水

- 徐发杰

推荐信息

-

平谷烧结银纳米银导电胶ssp2020代理,烧结银

平谷烧结银纳米银导电胶ssp2020代理,烧结银 -

楚雄半导体材料汉高ABLESTIKJM7000导电胶,JM7000导电胶

楚雄半导体材料汉高ABLESTIKJM7000导电胶,JM7000导电胶 -

邢台烧结银纳米银导电胶ssp2020配件

邢台烧结银纳米银导电胶ssp2020配件 -

门头沟烧结银纳米银导电胶ssp2020作用,烧结银

门头沟烧结银纳米银导电胶ssp2020作用,烧结银