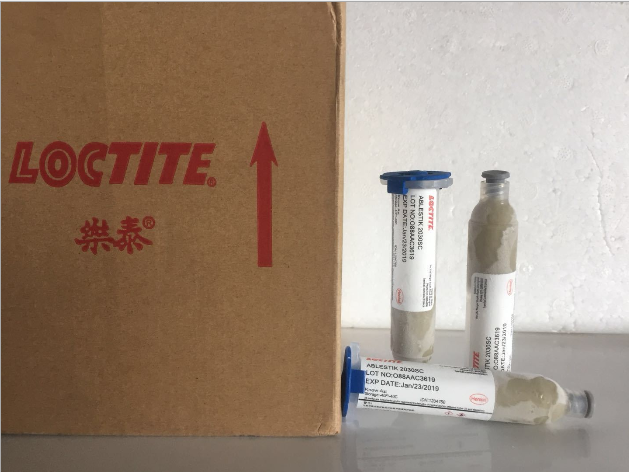

汉高LOCTITEABLESTIKABP2032S胶水汉高2032S

- ¥1.00 ≥ 1瓶

- 2023-05-11 11:29:01

- 金属类

- 汉高2032S,ABLESTIK ABP 2032S,2032S,LOC..

- 上海

- 上海环央化工科技有限公司

信息介绍

详细参数

汉高LOCTITE ABLESTIK ABP 2032S胶水 汉高2032S

LOCTITE ABLESTIK ABP 2032S provides the following product characteristics: Technology Epoxy Appearance Silver Cure Heat cure Product Benefits

● Electrically conductive

● Low temperature cure

● Good adhesion

● Good dispensing characteristics Application Die attach Key Substrates Au, Steel and Ag LOCTITE ABLESTIK ABP 2032S electrically conductive adhesive is designed as a Pb-free alternative to solder. It cures quickly at low temperatures for good stress control in large die size package applications. TYPICAL PROPERTIES OF UNCURED MATERIAL Viscosity, Brookfield CP51, 25 °C, mPa·s (cP): Speed 5 rpm 11,000 Thixotropic Index (5/6 rpm) 4.5 Work Life @ 25°C, hours 24 Shelf Life @ -40°C (from date of manufacture), days 365 Flash Point - See SDS TYPICAL CURING PERFORMANCE Cure Schedule 60 minutes @ 80°C Alternative Cure Schedule 3 minutes @ 150°C or 10 minutes @ 120°C Weight Loss Weight Loss on Cure, % 0.7 The above cure profiles are guideline recommendations. Cure conditions (time and temperature) may vary based on customers' experience and their application requirements, as well as customer curing equipment, oven loading and actual oven temperatures. TYPICAL PROPERTIES OF CURED MATERIAL Physical Properties Glass Transition Temperature (Tg) by TMA, °C 110 Coefficient of Thermal Expansion : Below Tg, ppm/°C 54 Above Tg, ppm/°C 162 Thermal Conductivity , W/(m-K) 1 Extractable Ionic Content, , ppm: Chloride (Cl-) <30 Sodium (Na+) <20 Potassium (K+) <20 Dynamic Tensile Modulus, DMA: @ 25 °C N/mm² 4,600 (psi) (667,173) @ 100 °C N/mm² 1,200 (psi) (174,045) @ 250 °C N/mm² 150 (psi) (21,755) Electrical Properties Volume Resistivity, ohm-cm 0.0002 TYPICAL PERFORMANCE OF CURED MATERIAL Die Shear Strength @ 25 °C: 2 X 2 mm Si die, kg-f : Sample cured 60 minutes @ 80°C: On Au 16 On Steel 15.5 On Ag 16

- 汉高2032S,ABLESTIK ABP 2032S,2032S,LOC..

- 导电银胶

- 上海

- 张萱

- 金属类

LOCTITE信息

-

手动渠道闸门、台湾手动渠道闸门销售价格面议

手动渠道闸门、台湾手动渠道闸门销售价格面议 -

郴市-矿山开采机械设备-厂家直销¥ 1

郴市-矿山开采机械设备-厂家直销¥ 1 -

丽水建筑工地洗车设备#丽水工地车辆洗车设备¥ 666

丽水建筑工地洗车设备#丽水工地车辆洗车设备¥ 666 -

拱墅机床回收/拱墅机床回收拱墅旧机床回收近期¥ 188

拱墅机床回收/拱墅机床回收拱墅旧机床回收近期¥ 188 -

怎么挑选--黄石聚丙烯酰胺)生产厂家¥ 7777

怎么挑选--黄石聚丙烯酰胺)生产厂家¥ 7777 -

罗源到晋城豪华汽车票价查询¥ 18

罗源到晋城豪华汽车票价查询¥ 18