65Mn50Mn弹簧钢热处理执行标准是GB/T1222交货状态产地厂家

- ¥5500.00 ≥ 1吨

- 2020-04-13 09:11:47

- 鞍山

- 65Mn 50Mn

- 65Mn弹簧钢板,50Mn刀刃钢,鞍山50Mn刀刃钢..

- 海南

- 喻尚上 15639797063

- 河南润禄贸易有限公司

信息介绍

详细参数

Spring steel 65 mn standards GB/T 1222-2007 annealing temperature is 750 ℃

热处理及冷拔硬化后,强度比较高,具有一定的柔韧性和可塑性;

After heat treatment and cold drawing hardening, the strength is relatively high, and it has certain flexibility and plasticity.

相同表面状态和完全淬透情况下,疲劳极限与五彩合金弹簧相当。

The fatigue limit is equivalent to that of the multicolored alloy spring in the same surface condition and full quenching.

但淬透性非常差,主要用于滴点大尺寸的弹簧,如调压调速调皮弹簧、测力弹簧、一般机械上的圆、方螺旋弹簧或拉成钢丝作小型机械上的弹簧。

But hardenability is very poor, it is mainly used for large size drop point of the spring, such as regulating speed naughty spring, spring load, general machinery of round, square spiral spring or pull wire for small mechanical spring.

中文名称:弹簧钢

Chinese name: spring steel

标准:GB/T 1222-2007

Standard: GB/T 1222-2007

特性

characteristic

材料名称:弹簧钢

Material name: spring steel

牌号:65mn

Brand: 65 mn

标准:GB/T 1222-2007

Standard: GB/T 1222-2007

*特性及适用范围:

* features and scope of application:

*化学成份

* chemical composition

碳 C 硅 Si 锰 Mn 硫 S 磷 P 铬 Cr 镍 Ni 铜 Cu

0.62~0.70 0.17~0.37 0.90~1.20 ≤0.035 ≤0.035 ≤0.25 ≤0.25 ≤0.25

*力学性能

* mechanical properties

屈服强度 Rs (MPa) 伸长率 δ10 (%) 断面收缩率 ψ (%) 抗拉强度 Rb(MPa)

≥785 14~21.5 不小于10 ≥980

*硬度

* hardness

热轧硬度 冷轧软态硬度 冷轧硬态硬度 热处理硬度

240~270HB 190~220HB 300~340HB 38~60HRC

*折叠热处理及规范

* folding heat treatment and specification

热轧钢材以热处理或不热处理状态交货,冷拉钢材以热处理状态交货。

The hot rolled steel is delivered in heat treatment or without heat treatment, and cold drawn steel is delivered in heat treatment.

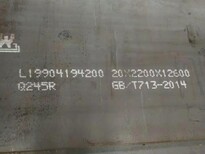

(2.0-16)*1250*C 莱钢 /热卷/热板

(2.0-16)*1250*C lai steel/hot roll/hot plate

50Mn (2.0-16)*1250*C 莱钢 /热卷/热板

50Mn (2.0-16)*1250*C lai steel/hot roll/hot plate

65Mn (2.0-16)*1010/1250*C 莱钢 /热卷/热板

65Mn (2.0-16)*1010/1250*C lai steel/hot roll/hot plate

*退火规范

* annealing specification

传统周期性球化退火工艺,退火温度750℃,保温2h,炉冷到温度(680±10)℃,保温3h,再炉冷到550℃以后,出炉空冷。

Traditional spheroidizing annealing process, periodically annealing temperature is 750 ℃, 2 h insulation, furnace cooling to the temperature (680 + 10 ℃, heat preservation, 3 h, again after the oven to 550 ℃ cold, empty out cold.

生产效率低,氧化脱碳率达22%-40%,表面硬度及弹性达不到要求。

The production efficiency is low, the oxidation decarburization rate is 22%-40 %, the surface hardness and elastic cannot meet the requirements.

不完全退火新工艺,退火温度(740±10)℃,保温4h,炉冷到550℃以后,出炉空冷。

Incomplete annealing technology, anneal temperature (740 + 10) ℃, insulation 4 h, furnace cooling to 550 ℃, from air cooling.

抗拉强度600-620Mpa、伸长率53.5%-40%,硬度209-214HBW金相组织为球化珠光体+少量点状珠光体,缩短了生产周期,节省能源。

The tensile strength of 600-620mpa, elongation of 53.5%- 40%, hardness 209-214hbw metallographic tissue is spherified pearlite + a few point pearlite, shorten the production cycle and save energy.

*退火新工艺

* new technology for annealing

传统退火工艺,退火温度730℃,保温13h,再炉冷到650℃以后,出炉空冷

Traditional annealing process, the annealing temperature 730 ℃, holding 13 h, again after the oven to 650 ℃ cold, empty out cold.

退火新工艺:退火温度(860±10)℃,保温45-60min,炉冷到(750±10)℃,保温3-3.5h,在炉冷至650-660℃以后,出炉堆冷或入保温坑缓冷。

Annealing processes: (860 + 10) ℃ annealing temperature, heat preservation for 45 to 60 min, furnace cooling to 750 + 10 ℃, heat preservation, 3-3.5 h, after the furnace cooling to 650-660 ℃, from pile of cold insulation or into the slow cooling pit.

金相组织符合要求:珠光体组织2.5-6级,以4级左右为佳,该工艺提率80%-。

The metallographic organization meets the requirements: the pearlite organization is 2.5-6, which is better than 4 or so, which increases the efficiency by 80% to .

*热处理

* heat treatment

65Mn低合金圆钢应具备高的弹性极限和高的屈强比,以避免弹簧钢在高载荷下产生变形;

65Mn low-alloy round steel must have high elastic limit and high yield ratio to avoid permanent distortion of spring steel under high loading.同时还要求有良好的淬透性和低的脱碳敏感性,使弹性极限大幅度降低;

It also requires good hardenability and low decarbonization sensitivity to reduce the elastic limit.

以及良好的表面质量,在冷热状态下容易加工成形和良好的热处理工艺性。

And good surface quality, easy to process forming and good heat treatment process in cold and hot condition.

在热状态下成型的弹簧热成型弹簧钢的热处理工艺。

Heat treatment process of spring steel with spring heat forming in hot state.

用这种方法成型弹簧钢多数是将热成型和热处理结合在一起进行的,而螺旋弹簧钢则大多数是在热成型后再进行热处理。

In this way, most of the spring steel is combined with heat and heat treatment, while the helical spring steel is mostly heat treated after hot forming.

这种弹簧钢的热处理方式是淬火+中温回火,热处理后组织为回火托氏体。这种组织的弹性极限和屈服极限高,并有一定的韧性。

The heat treatment of this spring steel is quenching + medium temperature-temperature-temperature-temperature-temperature-temperature-temperature-tempering. he elastic limit and yield limit of this group is high and has some toughness.

采用全新的理念和方法,创新性地进行稳定性控制技术开发对容易在这"0.4秒"时间里产生的"轧破、甩尾"等问题的形成机理进行认真分析,从减少轧辊受损、减少尾部跑偏等多个方面开展工作,经过3年多的软件程序开发、跟踪试验、评估、分析确定合理的工艺参数.

Adopt new ideas and methods, innovative for stability control technology development to the most easily produced in the "0.4" time "squeeze broken, spin" issues such as the formation mechanism of serious analysis, thus reducing the roll is damaged, reduce the tail running deviation, and other aspects to carry out the work, after more than three years of software program development, tracking, testing, evaluation, analysis to determine the reasonable process parameters.

65Mn 钢板强度、硬度、弹性和淬透性均比65号钢高,具有过热敏感性和回火脆性倾向,水淬有形成裂纹倾向。

The strength, hardness, elasticity and hardenability of the 65Mn steel plate are higher than that of no.65 steel, which has the tendency of superheat sensitivity and tempering brittleness, and the water quenching has the tendency of forming crack.

退火态可切削性尚可,冷变形塑性低,焊接性差。

The annealing state can be machinable, cold deformation plastic and poor welding.

受中等载荷的板弹簧,直径达7-20mm的螺旋弹簧及弹簧垫圈.弹簧环。

The medium - loaded plate spring with a diameter of 7-20mm coil spring and spring washer.

高耐磨性零件,如磨床主轴、弹簧卡头、精密机床丝杆、切刀、螺旋辊子轴承上的套环、铁道钢轨等。

High wear resistant parts, such as grinder spindle, spring card head, precision machine tool wire rod, cutter, spiral roller bearing ring, railway rail, etc.

喻尚

Yu shang:

舞钢地址:舞钢市经济产业园区建设路195号

Address: no. 195, construction road, economic industrial park, Wugang city

郑州地址:郑州市航海路正商国际大厦9号0903室

Zhengzhou address: room 0903, no. 9, ZhengShang international building, Zheng Zhou

- 65Mn弹簧钢板,50Mn刀刃钢,鞍山50Mn刀刃钢..

- 碳合结钢

- 海南

- 喻尚上

- 鞍山

- 65Mn 50Mn

弹簧钢信息

-

湖北鄂州过轨管厂家¥ 16

湖北鄂州过轨管厂家¥ 16 -

高密到昭通汽车高速多久到¥ 1

高密到昭通汽车高速多久到¥ 1 -

三滚轴路面摊铺机219滚轴式摊铺机桥面振动摊铺振动梁¥ 8000

三滚轴路面摊铺机219滚轴式摊铺机桥面振动摊铺振动梁¥ 8000 -

快速变现古董古玩瓷器字画钱币古玉快速成交面议

快速变现古董古玩瓷器字画钱币古玉快速成交面议 -

(客车)从潍坊到馆陶(专线汽车票价)提前订票¥ 88888

(客车)从潍坊到馆陶(专线汽车票价)提前订票¥ 88888 -

2020年无轨胶轮电动平车生产厂家¥ 11000

2020年无轨胶轮电动平车生产厂家¥ 11000