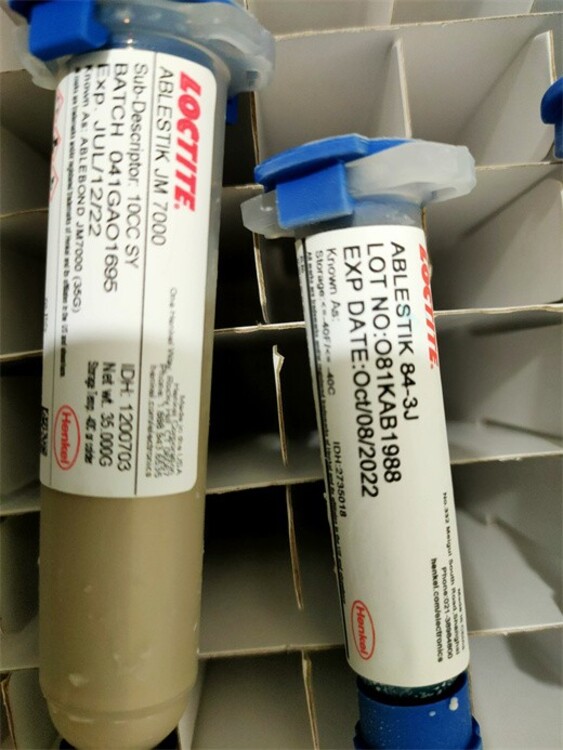

潮州厚膜电路汉高ABLESTIKJM7000导电胶,乐泰导电胶

- 面议

- 2024-10-28 15:59:58

- 汉高ABLESTIKJM7000导电胶,JM7000导电胶,..

- 广东中山

- 徐发杰 18515625676

- 北京汐源科技有限公司

信息介绍

详细参数

TYPICAL PROPERTIES OF UNCURED MATERIAL

Viscosity, HAAKE RV-20 Rotoviscometer, mPa·s (cP):

Cone 1º @ Shear rate 22 s

-1 9,000

Work Life @ 25°C, hours 8 to 16

Shelf Life @ -40°C (from date of manufacture), days 365

TYPICAL CURING PERFORMANCE

Cure Schedule

30 minutes @ 150°C

Suggested temperature cures are from 150 to 350ºC. For

applications requiring higher electrical conductivity, a cure cycle of 15

minutes @ 300ºC is recommended. Product properties will not be

reduced by subsequent post die attach thermal exposure, i.e.,

wirebond, and/or lid seal up to 370ºC.

TYPICAL PROPERTIES OF CURED MATERIAL

Physical Properties

Coefficient of Thermal Expansion, :

Below Tg, ppm/°C 33

Glass Transition Temperature (Tg) by TMA, °C 240

Bulk Thermal Conductivity, W/(m-K):

@ 90°C 1.1

@ 165°C 1.0

Tensile Modulus, DMTA :

Cured 30 minutes @ 300ºC N/mm² 10,000

(psi) (1,450,377)

Extractable Ionic Content, @ 100°C:

Chloride (Cl-) <10

Sodium (Na+) <15

Potassium (K+) <15

Decomposition (in N2):

TGA analysis @ 10ºC/ minute ramp from 25 to 400

ºC

@ 340ºC, % 0.2

@ 400ºC, % 0.3

Electrical Properties

Sample cured 30 minutes @ 300ºC

Volume Resistivity, ohm-cm ≤0.01

TYPICAL PERFORMANCE OF CURED MATERIAL

Die Shear Strength:

2 X 2 mm Si die, kg-f,

cured 20 minutes @ 150ºC

Substrate DSS

Ag/Cu LF ≥5

Tensile Strength :

cured 30 minutes @ 300ºC, MPa

After Cure After 1000 TC'C"

>17 >17

Radius of Curvature:

Si die on Alumina, meters

cured 30 minutes @ 300ºC

Chip Size: ROC

15 x 15 mm > 5

- 汉高ABLESTIKJM7000导电胶,JM7000导电胶,..

- 导电银胶

- 广东中山

- 徐发杰