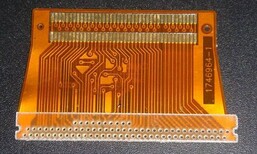

单面铝基板UL仅燃烧认证

- ¥2.00 ≥ 1件

- 2019-01-25 11:28:07

- 产品认证

- 电池芯UL1642认证,线处理UL认证,彩虹灯管..

- 广东深圳

- 陶静 13913142465

- 深圳市优尔检测技术有限公司

信息介绍

详细参数

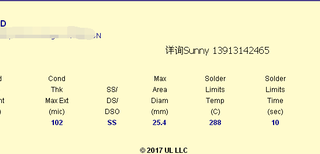

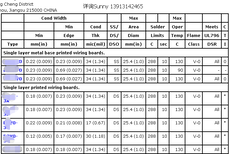

These requirements apply to rigid printed-wiring boards and flexible printed-wiring board for use as components in devices or appliances. Compliance with these requirements does not indicate that the product is acceptable for use as a component of an end product without further investigation.

1.2 The flexible printed-wiring boards covered by these requirements consist of conductors affixed to insulating base film, with or without a cover-lay film, with midboard connections.

1.3 These requirements do not cover flexible printed-wiring boards of laminated-film construction in which the conductors are parallel to each other and are completely covered by the base film with only point-to-point end connections.

1.4 These requirements do not apply to flexible, flex-to-install, rigid, and multilayer rigid flex composite interconnect constructions with and without stiffener and adhesive materials as flexible materials interconnect constructions (FMIC's) for use as components in devices or appliances – that are covered by the Standard for Flexible Materials Interconnect Constructions, UL 796F.

Cover

Transmittal

Table of Contents

Body

INTRODUCTION

1 Scope

2 Glossary

3 Units of Measurement

4 Measurement Accuracy and Testing Conditions

5 Supplementary Test Procedures

6 References

7 General

CONSTRUCTION

8 General

9 Base Materials

9.1 General

9.2 Metal-clad base material

9.3 Direct support

10 Conductors

10.1 Materials

10.2 Silver

10.3 Conductive coating

10.4 Edges and width

10.5 Pattern surfaces

10.6 External copper foil or cladding process weight

10.7 Midboard conductor

10.8 Edge conductor

10.9 Maximum unpierced conductor area

10.10 Contact surface plating

10.11 Plated-through holes

10.12 Additional conductive plating

10.13 Solder limits

10.14 Pattern

11 Adhesives for Conductor Bonding

12 Processes

12.1 General

12.2 Multiple-site processing

13 Permanent Coatings

13.1 General

13.2 Permanent coatings program

14 Plugged-Hole Materials

15 Embedded Components

16 Singlelayer (Singlesided and doublesided) Printed-Wiring Boards

16.1 General

16.2 Metal-clad (MCIL/CCIL) base material program

17 Multilayer Printed-Wiring Boards

17.1 General

17.2 Assembly

17.3 Mass laminate printed wiring boards

17.4 Electrical insulation

17.5 Laminations

17.6 Dissimilar dielectric materials evaluation

17.7 Interlayer connections

17.8 Metal-clad laminate and prepreg materials

18 Metal Base Printed-Wiring Boards

18.1 General

18.2 Vertical flammability evaluation for metal base PWBs

18.3 Bond strength evaluation for metal base PWBs

19 Flexible Printed-Wiring Boards

20 Variations In Printed-Wiring Board Construction

PERFORMANCE

21 Test Samples

22 Data Collection

23 Microsection Analysis

23.1 General

23.2 Test samples

23.3 Etching the sample surface

23.4 Material and test pattern parameter examination

24 Thermal Shock

25 Flammability

25.1 General

25.2 Samples

25.3 Conditioning

26 Bond Strength

26.1 After thermal shock

26.2 As received

26.3 Oven conditioning

27 Delamination and Blistering

28 Dissimilar Dielectric Materials Thermal Cycling Test

28.1 General

28.2 Thermal cycling

29 Plating Adhesion

30 Conductive Paste Adhesion Test

31 Dielectric Materials Intended for Use in Fabricating High Density Interconnect (HDI) Type Constructions

31.1 General

31.2 HDI Vertical flammability evaluation

31.3 HDI Bond strength, delamination and blistering evaluation

31.4 Test programs for HDI PWB construction variations

32 Silver Migration Test

32.1 General

32.2 Procedure

32.3 Results

MARKINGS

33 General

FOLLOW-UP INSPECTION

代理范围

部分:初次申请

(一)单层板全流程申请

(二)预制多层板全流程申请

(三)多层板全流程申请

(四)单层板+多层板)全流程申请

(五)金属基板全流程申请

(六)HDI板全流程申请

(七)柔性线路板全流程申请

第二部分:物料/单项制称新增

(一)单种型号的基板申请

(二)单种型号PP申请

(三)单种型号的阻焊油墨申请

(四)新增工艺步骤

(五)新增外包商

(六)新增多个生产地

(七)新增制造商

(八)线宽变更/塞孔增加

(九)变更基板厚度/燃烧等级/铜厚/

(十)新增“▲”标志

(十一)裸铜面积/焊接温度/制程温度变更

第三部分:翻译服务

(一)UL文件中文翻译/UL跟踪检验细则中文翻译

(二) UL标准中文翻译

(三)UL往来信函/E-mail中文翻译

第四部分:补充服务

(一)UL证书镀金表框

(二)黄卡申购

(三)订购UL标准

第五部分:全年承包服务

(一)负责全年的材料报备及新增制程的申请及UL相关文件资料维护。

(二)负责全年的UL跟踪检查维护和与UL工程师的沟通交流。

(三)提供一年免费的电话咨询,UL英文资料翻译及Email解答

(四)提供1次/月的现场改善指导;

(五)提供UL检查前培训辅导

第六部分:

(一)其它和UL有关的相关产业。

联系人:陶静Sunny :1822971259

- 电池芯UL1642认证,线处理UL认证,彩虹灯管..

- 认证中介

- 广东深圳

- 陶静

- 产品认证

电池芯UL1642信息

-

南昌学草图大师室外效果图制作需要CAD基础吗?面议

南昌学草图大师室外效果图制作需要CAD基础吗?面议 -

o型密封圈南召县面议

o型密封圈南召县面议 -

甘肃射线防护门,甘肃射线防护板面议

甘肃射线防护门,甘肃射线防护板面议 -

厂家现货脚手架及配件盘扣碗扣轮扣脚手架量大优惠欢迎询价¥ 6200

厂家现货脚手架及配件盘扣碗扣轮扣脚手架量大优惠欢迎询价¥ 6200 -

太原兴盛专业安装中空玻璃安装舞蹈室镜子安装地弹簧面议

太原兴盛专业安装中空玻璃安装舞蹈室镜子安装地弹簧面议 -

FPM氟橡胶O型圈鹰潭面议

FPM氟橡胶O型圈鹰潭面议